Dr Sauer & Partner’s MD in the UK, Brian Lyons, recently gave a presentation to the LBA/BASF Sprayed Concrete Workshop held at the Hagerbach Tunnel Test Facility in Switzerland. The talk, titled '10 Years of SCL' summarised the key developments in sprayed concrete in the UK over this period including:

- Health & Safety initiatives such as the Option A joint developed by Dr. Sauer & Partners with Dragados for the LU Bank Station Capacity Upgrade Project. The detail provides a fully mechanised radial joint formation removing tunnel construction personnel from the face and areas under freshly sprayed concrete.

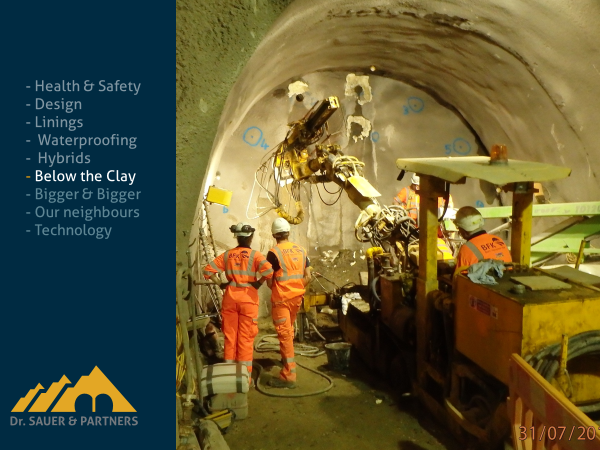

- Adoption of large diameter SCL construction for non-cohesive material as demonstrated at the Farringdon Crossrail Station. The majority of SCL in the UK had been in London Clay but Crossrail’s vertical alignment required tunnelling in the Lambeth Group and Thanet Sand. For these units, extensive probing, dewatering/depressurisation and grouting were used by Dr. Sauer & Partners with BAM Ferrovial Kier to confirm ground conditions and apply mitigation measures to successfully tunnel through strata that would have been considered not feasible for SCL ten years earlier.

- Innovations in lining design allowing combined linings to realise efficiencies in overall lining thicknesses compared to a decade ago.

- Ongoing improvements in sprayed and sheet waterproofing systems and details

- The development of Hybrid SCL/squareworks solutions to optimise mechanisation of the tunnelling process and reduce HAVs/manual handling issues associated with traditional tunnelling

Numerous examples from the LU Bank Station Capacity Upgrade project were provided by Brian, which in addition to safety benefits have delivered significant cost and time savings.

Brian concluded that the use of SCL in the UK although already proven ten years ago, has seen significant advances in the last decade. These particularly address safety, cost and programme challenges, development of measures for dealing with non-cohesive and potentially water-bearing units, all of which have pushed the boundaries of implementing SCL and helped set the UK at the forefront of SCL tunnelling development.