Tunnel construction at the Bank Station Capacity Upgrade (BSCU) project started in February 2017. The BSCU Project will boost capacity by 40 per cent. This includes; creating a new Northern line tunnel, platform and circulation spaces, and an additional entrance on Cannon Street, the introduction of step-free access to the Northern line and improved access to the DLR platforms, and a moving walkway between the Central and Northern lines to reduce customer journey times. About 85% of the SCL primary lining tunnelling works underneath The City, London’s financial district is completed. This already equates to 1km of new tunnels. However, creating space through a dense maze of existing and operational tunnels, building foundations and historic assets is not an easy job. To cope with these challenges Dr. Sauer & Partners as SCL expert consultant for the contractor Dragados has developed innovative design solutions and continues to supervise their successful implementation during construction. Such is the case for a load transfer structure of the existing pile foundation for one of the buildings within the works area.

Among others, one of the key features of the BSCU project is the new Northern line southbound platform tunnel. It will be connected with the existing southbound running tunnel via two new running tunnels to the north and south of the new platform tunnel. Most of the running tunnels have been completed with only the tie-in connections at both ends left to be excavated, which is scheduled to be carried out later in the project. During running tunnel construction towards the north, a well expected obstruction has been encountered – the foundation piles of an existing building with deep pile foundations. These piles intercept with the alignment of the new running tunnel that will connect the new platform to the existing line. Four of the existing piles were deemed necessary to be cut and replaced by a load transfer structure. This required extensive assessments on the building foundation, and in order to ensure the building’s structural integrity a building damage assessment has been carried out.

The solution to the above is structures that can bear the load of each cut foundation pile. Accordingly, Dr. Sauer & Partners delivered the design of the load transfer structures to support the cut piles. These structures, although integrated in the running tunnel, are engineered as separate structures, isolated from the tunnel lining. Since structural tunnel linings are designed to withstand all loads that will be experienced from construction to the end of design life, these structures were designed not only to withstand the current transferred loads from the piles above, but also to support possible additional future loads should the building change in the future.

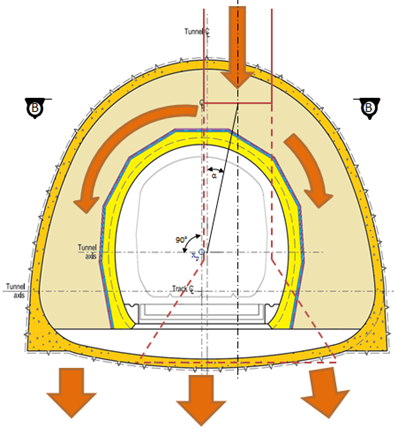

The load transfer mechanism. Loads transferred from the pile, and through the transfer structure to the ground.

The shaft and the underream of an exposed foundation pile; thorough monitoring and as-built documentation prior to cutting and removal.

The structural mechanism behind this can be explained as follows: the load from the pile is transferred to an arched reinforced concrete structure built around the cut end. The structure bridges over the new Northern line southbound tunnel and delivers the loads to a reinforced concrete invert. The loads then are being diffused to the ground.

In the design of the structures, both empirical and finite element analyses were employed. First, the initial dimensioning of the cross section was executed in accordance with the Eurocode 2, maintaining ground bearing capacity at all times. After the required geometry was established ensuring that the arched structure can bear the loads of the pile as a footing, the transfer structures were inserted in the general BSCU finite element model to assess whether the enlarged tunnel geometry is capable of taking the ground loads. Moreover, the soil-structure interactions were determined. With the FE analysis data at hand, the final geometry was refined to produce the most efficient results. The steel reinforcement design was further enhanced by assessing the stress distribution in the body of the transfer structures.

In the crown of a transfer structure a dense cage of reinforcement is fabricated.

In just under five months and with a little more than 600 m3 of concrete, 35 tons of steel, the transfer structures were completed. Through a combination of careful excavation, detailed monitoring and full comprehension of the design by all that were involved in the construction, the three transfer structures reached successful completion in late November 2018 with hardly any impact on the building above.

The three transfer structures finalised.